Tin Oxide

Tin oxide is a white, inert and highly chemically and thermally stable material. Its inertness is the reason for its environmentally friendly and non-toxic profile. Here at Keeling & Walker, we use sophisticated processes and over 80 years of manufacturing experience to produce highly refined and tailored synthetic tin oxides.

Superlite

Our Superlite range includes the most versatile grades of tin oxide that we produce at Keeling & Walker. A consistent raw material quality and rigorous analytical control of its chemical and physical properties is the key to Superlite’s high performance in various applications.

Applications of Superlite include:

- Raw material for ceramic colour pigments

- Opacifier for Glazes

- Refining additive in the glass industry

- Abrasives in polishing products

- Formulation of electroceramics

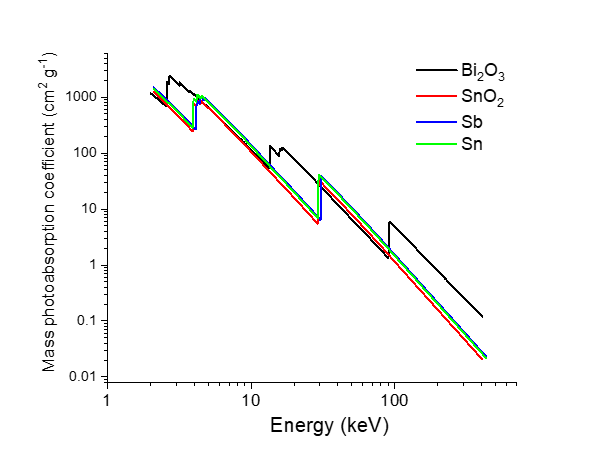

- Shielding material for protection against X-Rays

| Tin Oxide Grade | Advantage |

|---|---|

| Superlite | Most versatile grade |

| Superlite C | Low Pb grade |

| SPG | Cost effective grade for ceramic pigments |

| SV5 | Free flowing powder grade |

Thermox

Thermox tin oxide grades are manufactured by a unique process proprietary to Keeling & Walker.

With Thermox RL, Keeling & Walker offers the finest thermal grade of tin oxide on the market.

Thermox tin oxides show superior performance results in sintering processes.

Applications of Thermox grades include:

- Electrodes for LCD glass manufacturing

- Glass Refining Additives

- Friction Materials, brake pads

- Electrical contact materials

- Ceramic colour pigments

| Thermox Grades | Advantage |

|---|---|

| VS | Excellent sintering properties |

| VN | Excellent sintering properties |

| EFGE | Multipurpose application |

| RL | D50 = 0,2 µm, finest grade |

High Purity Tin Oxides

High-tech applications are often only viable if raw materials with specific high purity levels are available.

Ultrathin metal or oxide layers needed in the electronics and semiconductor industry are made via evaporation or sputtering methods. High purity raw materials are the common basis for these processes and enable the formation of defect-free thin films with the required electrical or optical properties.

Here at Keeling & Walker, we provide high purity tin oxides with a minimum purity of 99.99%. We can also provide tin oxide with specific limits for individual trace elements. We offer high purity materials based on thermal oxidation, as well as from wet chemical processes.

Thermox RL-HP offers a small particle size and a uniform and narrow particle size distribution, with excellent sintering properties to allow highly dense and stable target materials to be manufactured.

For radiochemical applications, high purity alphastannic acid (HPASA), as a largely amorphous tin oxide, offers high ion-exchange capacity for specific radionuclides, a well-defined particle size distribution and is manufactured in an environment suitable for pharmaceutical use.

Applications of High Purity grades include:

- Laser Glass manufacturing

- Glass Refining Additive for low expansion Glass

- Sputtering Target materials

- Advanced Battery materials

- Medical and Cosmetic applications

| Tin Oxide Grades | Advantage |

|---|---|

| Thermox RL-HP | Highest purity and smallest uniform particle size distribution |

| HPMSA | 200 m2/g BET surface area |

| HPTO | Chemically precipitated with high bulk density |

| HPASA | Amorphous material for medical application |

Specialty Tin Oxides

We will research and develop Tin Oxide properties to produce you a high-quality component to your specific application.

Tailoring the properties of tin oxides to match the requirements of the diverse applications of our customers is one of our strengths here at Keeling & Walker.

Whether that may be a material with a high BET surface area, high reactivity for use in catalyst applications, or the opposite in electrical contact materials, or tailored materials for gas sensor applications, we can offer a product to suit your needs.

If you can´t find what you are looking for, then please challenge us! We are always open for co-operations.

Applications of Specialty Oxide Grades include:

- Friction materials, brake Pads

- Electrical contact materials

- Coatings with high abrasion resistance

| Tin Oxide Grades | Advantage |

|---|---|

| CS-1 | D50 = 1.5 µm for glass applications |

| CVS 6 | D50 = 6 µm for electrical contact application |

| CS grades | Special tailor made products for electrical contact materials with very high stability |

| CSC-JXA | Tin Oxide coated with Indium Oxide for electrical contact applications |

Tin Oxide Nanodispersions

Keeling & Walker manufactures a range of aqueous Tin Oxide Nanodispersions with typical particle sizes around 10 – 20 nm, which allow the formulation of highly transparent coatings. Due to a unique process it is possible to offer nanodispersions with virtually no residual salt content, guaranteeing a high purity of the materials. The dispersions show excellent transmission in the visible and NIR light range.

Typical applications for the Tin Oxide Nanodispersions are:

- Coatings for gas sensors

- Electrode coatings

- Antireflection coatings for solar cells

- Electron Transport Layers (ETL Layers) in perovskite solar cells

- Hydrophilic coatings on nonpolar materials

- Catalytic coatings.

- Coatings with adjusted refractive indices

| Tin Oxide Nanodispersions | Advantage |

|---|---|

| ADTOS | 10% solids ammonia stabilized dispersion in water |

| AMSOL | 17 – 21% solids dispersion stabilized by aminoalcohol |

| HTOD | 27 – 30% solids dispersion stabilized by KOH in water |

Stannic Acids

Doping the porous structure of metastannic acid with precious metals can produce materials for use in sensor applications. These materials are suitable for the detection of different gases for environmental and air quality control. Similar processes with other metal oxides can generate catalysts for petrochemical processes.

Applications of Stannic Acid Grades include:

- Ceramic Colour Pigments

- Catalyst Carrier material

- Advanced Battery materials

| Tin Oxide Grades | Advantage |

|---|---|

| Metastannic Acid | 200 m2/g BET surface area and high reactivity |

| HSATO | 35 m2/g BET for catalyst application |

X-Ray Radiation Protection – what do with the raising costs?

The use of ionizing radiation is an indispensable part of modern medical treatment. The use of radiation shielding apparel for the personnel in

Our products are manufactured to the ISO 9001 Quality Assurance Standard. Learn about Keeling and Walker's commitment to quality.

We research & develop products for the needs of our customers from a vast range of different industries; glass, ceramics, electrical and many more.